White Papers

The past 3 years have been some of the most disruptive ever for the Global logistics industry, with a Worldwide pandemic and the first war on the European mainland for over 70 years breaking out.

When COVID-19 turned the world upside down, it also sparked an immense amount of innovation. What individuals and businesses thought was impossible previously turned possible, and what wasn’t a priority before soon became urgent.

Packaging solutions that meet the needs of the biopharmaceutical industry while offering added cost benefits have become integral as more temperature controlled biologics and cell & gene therapies begin to dominate the market.

Cold chain packaging and shipping considerations change as an organization shifts from clinical to commercial operation, and new challenges have impacted shipping in general since the advent of COVID-19.

As more new biologics and cell and gene therapies enter the market, the need for reliable, demonstrable temperature control during shipping has become paramount to pharmaceutical companies’ overarching strategy.

For a large number of cold chain operations, some form of real-time or just-in-time monitoring is essential in order to protect the costly, high-value payloads that require low temperature or frozen storage.

Enabling the commercial shipment of pharmaceuticals is rife with complexity: the logistics, economy and safety concerns that attend bulk transportation necessitate solutions optimized to simplify transfer, lower costs and extend temperature controlled storage.

The considerations that accompany cold chain distribution at the commercial level are vast.

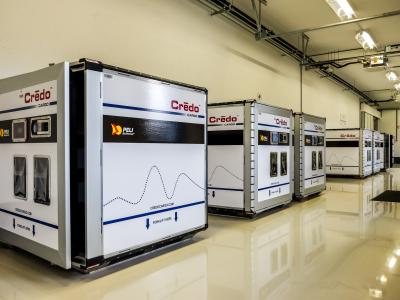

Vaporized liquid nitrogen is currently the only workable means of maintaining the ultra-cold temperatures necessary for certain therapeutics and tissue samples.

Enrolling patients in clinical trials has become an increasingly challenging task.

According to key opinion leaders in biopharma cold chain, the biopharma industry is increasing its pace to prioritize sustainability in business and operational strategies. Nearly half of all respondents already always factor sustainability into cold chain purchasing decisions.

A report looking into differing types of temperature controlled packaging (single use, reusable, passive, active) and its impact on the environment

As strong growth continues across the global pharmaceuticals industry, the sub-category of temperature-controlled products is surging ahead.

A report looking at the ways in which pharmaceutical products are shipped worldwide is changing as new technologies allow customers to trace, trace and pack more effectively

It is the goal of this research to identify current packaging options that limit this environmental impact.

Active or Passive? - this White Paper gives guidance on making the optimum choice when bulk shipping temperature sensitive pharmaceutical products.

The challenge of controlled room temperature shipments includes limitations of water-based coolant systems, profile manipulation, and conditioning process control.